COLD FRESH FRUIT STORAGE

To address long-term preservation challenges, high product turnover, and damage from repeated handling, a cold chain warehousing system was implemented combining four-way shuttle cars, an automatic fruit sorting line, and manual forklifts.

The solution enabled high-density storage with oxygen-free and high-humidity environments. Results included a significant reduction in fruit damage, improved inventory organization, and optimized space usage. The warehouse features 14,880 storage locations across 6540㎡, operating at -5°C to 0°C, supported by 8 shuttle systems and 10 vertical conveyors.

Phased deployment and equipment scalability support long-term storage and precise handling for temperature-sensitive produce.

REFRIGERATED STORAGE AUTOMATION

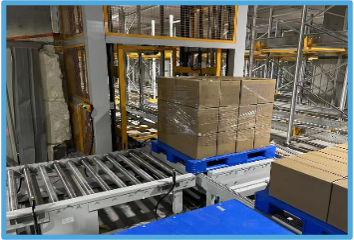

To increase storage density and improve picking efficiency in ultra-low temperature environments, a fully automated cold storage solution was deployed. The system featured in-warehouse automatic sorting and handling to replace traditional manual operations and meet a throughput target of 40 pallets/hour (inbound + outbound).

The warehouse spans 2,350㎡ with 1,200 storage locations and operates in ambient temperatures ranging from -18°C to -25°C. The solution incorporated 4 four-way shuttle systems and 2 vertical conveyors to ensure fast, reliable movement of frozen goods with minimal labor.

The deployment significantly improved throughput, optimized space utilization, and laid the foundation for scalable cold chain logistics.