CROSS BORDER E-COMMERCE FULFILLMENT

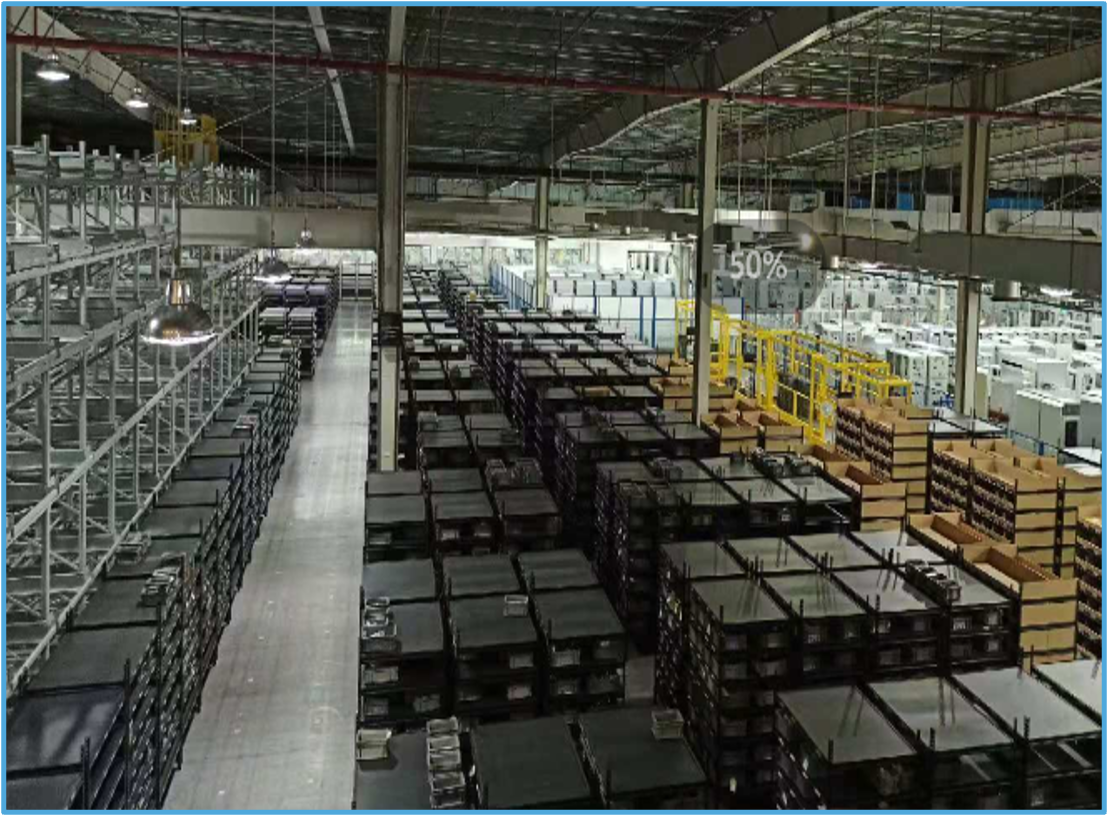

A 30,000 m² warehouse was equipped with 4-way shuttles, 100+ GTP robots, 100+ sorting AMRs, and 4 robotic arms.

Robotic arms and AMRs worked together for automated labeling, dimensioning, and exception handling. By integrating traditional and flexible automation, the warehouse achieved a fully touchless operation.

Results included a 200% increase in storage capacity, ~60% labor reduction, and significantly improved inbound/outbound efficiency.

FOOTWEAR FULFILLMENT

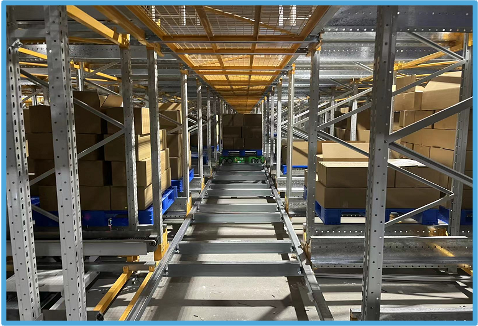

A 13,700 m² warehouse with 9m clear height adopted a hybrid solution combining 4-way shuttles and GTP systems. The upper zone holds 14,550 pallet locations across 3 tiers, while the lower zone includes 3,481 GTP picking shelves.

Equipped with 10 shuttles, 3 hoisters, and 37 P800 AMRs, the system handles 36 pallets/hour inbound and 169 order lines/hour outbound. The solution enhanced storage density, reduced labor intensity, improved efficiency, and remains flexible for future growth.