Inbound receiving involves manual quality checks, unloading, palletizing, barcode binding, and system data entry. Workers manually verify, palletize, bind barcodes, and check-in goods upon arrival.

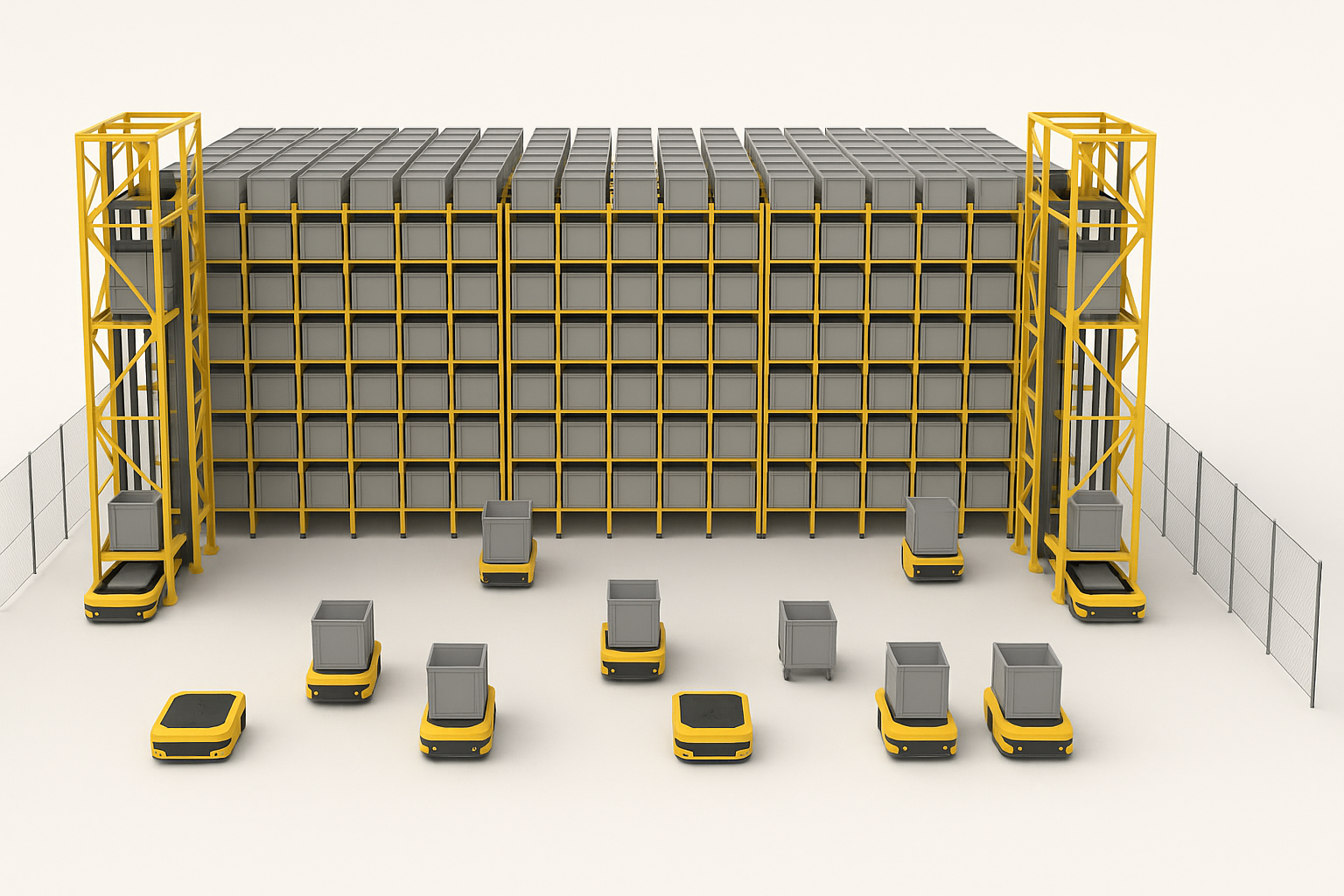

Our intelligent shelving solution optimizes product placement with dynamic slotting algorithms that reduce travel time and increase storage density, while continuously adapting to changing inventory patterns.

Traditional shelving operations rely on forklifts, manual labor, and semi-automated WMS recommendations. Inefficient storage allocation leads to poor picking efficiency and slow fulfillment.

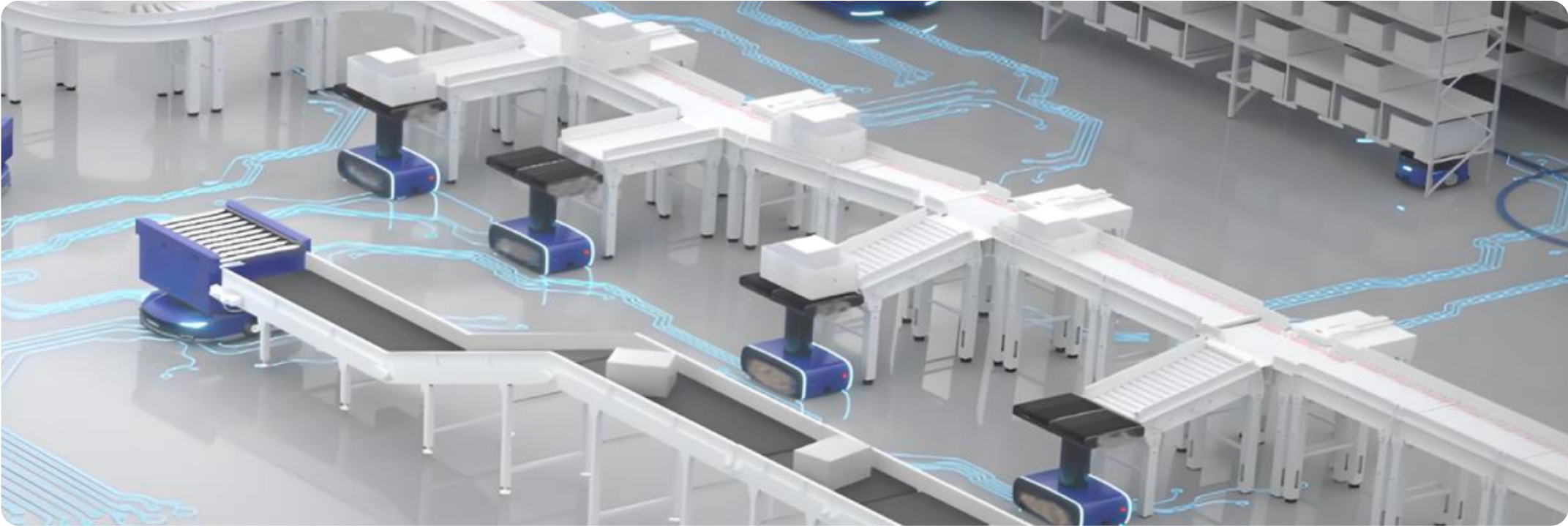

Picking relies heavily on manual paper orders/terminals, causing low efficiency, errors, and fatigue. Traditional systems (shuttle, rotating racks) have poor scalability and ROI.

Traditional storage (fixed racking/ASRS) leads to only 60–70% space utilization, with high initial investment and maintenance complexity.

Sorting typically relies on manual experience or semi-automatic sorters, leading to limited parcel compatibility, frequent breakdowns, and suboptimal ROI.