GROCERY & RETAIL

FLEXIBLE STORAGE FOR SEASONAL SKU FLUCTUATIONS

High SKU diversity and seasonal inventory shifts overwhelm traditional warehouse systems.

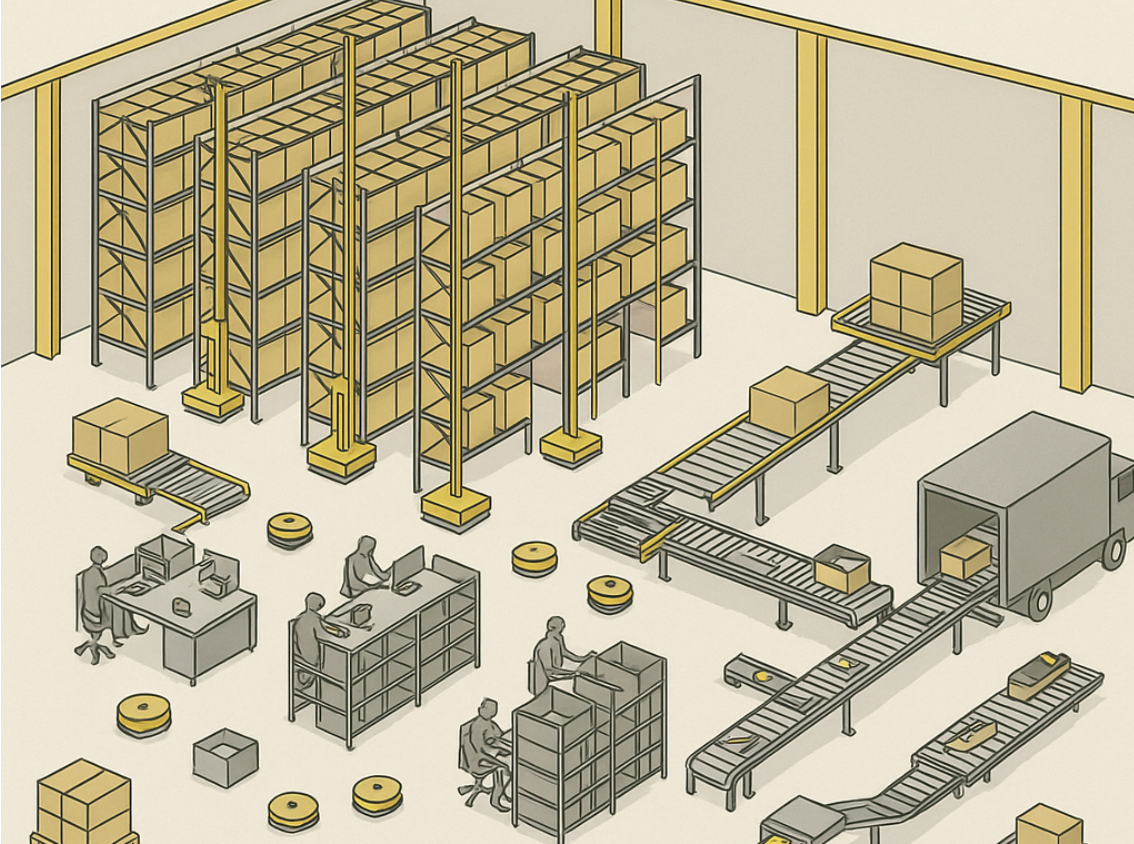

Our Solution: AMR-Based Goods-To-Person System

Supports mixed formats—totes, pallets, cartons, irregulars.

HIGH-DENSITY STORAGE FOR BULK RETAIL GOODS

Items like beverages, oil, and snacks require high-volume storage.

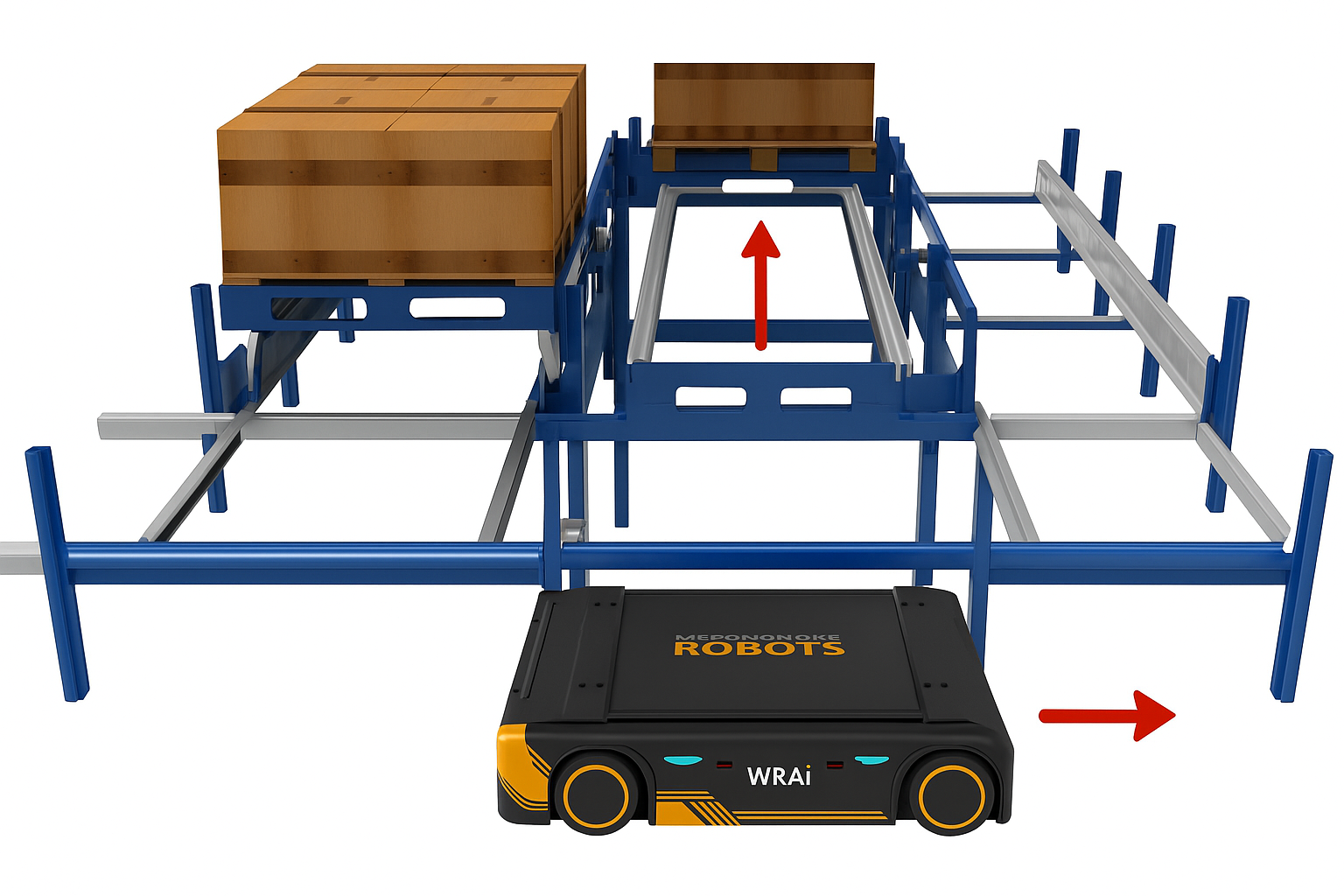

Our Solution: Pallet Four-Way Shuttle System

Fully automated solution that leverages vertical and deep-rack layouts.

SEQUENCED PICKING FOR SMART STACKING

Retailers must follow strict pallet stacking rules (e.g., heavy-on-bottom).

Our Solution: AMR-Based Sequenced Picking System

Ensures AMRs deliver items to pick stations in precise stacking order.

SCALABLE CAPACITY FOR PEAK DEMAND

Seasonal promotions like Black Friday cause order surges.

Our Solution: Hybrid AMR + Fixed Automation Model

Fixed systems handle steady loads; AMRs flexibly absorb demand spikes.

APPAREL

HIGH RETURN RATE / LOW SORTING EFFICIENCY

Return rates in apparel e-commerce reach ~35%.

Our Solution: AMR Shelf-To-Person Returns System

Doubles processing efficiency, supports flexible deployment.

SEASONAL INVENTORY VOLATILITY

SKU layouts must shift rapidly for seasonal promotions.

Our Solution: AMR + Mobile Shelves

Real-time SKU zone reallocation based on sales volume.

HIGH SKU COMPLEXITY / LOW ACCURACY

Footwear & apparel SKUs vary by color, size, gender, width.

Our Solution: AMR-Driven Fulfillment

Supports shelf/tote/pallet-to-person models.

3PL

DIFFICULT DATA INTEGRATION ACROSS SYSTEMS

Clients often use diverse and complex WMS or ERP systems.

Our Solution: Standardized API-Driven WMS/WES

Unified APIs seamlessly integrate with client-side WMS, ERP, and MES. Minimizes custom development, reduces integration costs, speeds deployment.

SEASONAL INVENTORY VOLATILITY

Traditional fixed zoning models lead to underutilized space (avg. <65%) and costly changes.

Our Solution: Dynamic Slotting + Modular AMRs

Deep RL-powered allocation system adjusts zone boundaries in real time. Modular AMRs and racking enable fast reconfiguration.

HIGH SKU COMPLEXITY / LOW ACCURACY

Peak seasons bring 40% temp workers → high forklift error/damage.

Our Solution: AMR-Driven Goods to Person Systems

Reduces forklift reliance, cuts walking distances, adapts to real-time volumes.

COLD CHAIN

LOW STORAGE DENSITY IN -25°C ENVIRONMENTS

Most cold storage sites still rely on manual forklifts and static racking.

Our Solution: Pallet-Based Four-Way Shuttle System

Operates within -25°C zones to enable 30–60% higher storage density.

MANUAL PICKING IS SLOW AND UNSUSTAINABLE

At -25°C, manual picking speed drops by 40%.

Our Solution: Shuttle + Conveyor + AMR Hybrid Workflow

Transfers outbound picking to external AMRs.

MANUFACTURING

LOW EFFICIENCY IN RAW MATERIAL HANDLING

Manual forklift transport has low speeds (2–3 km/h).

Our Solution: AGV/AMR-Based Material Transport

Automates movement between storage and production lines.

LOW WAREHOUSE SPACE UTILIZATION

Traditional beam racks only reach 60–70% utilization.

Our Solution: Four-Way Shuttle + Smart Storage

Boosts utilization to 90%, reduces aisle space to 15%.

HIGH ERROR RATE IN MANUAL PICKING

Manual picking error rates reach 5–8%.

Our Solution: AMR + Vision-Guided Component Picking

Visual recognition + laser navigation reduce errors.