Our comprehensive suite of warehouse management software provides end-to-end solutions for optimizing your logistics operations.

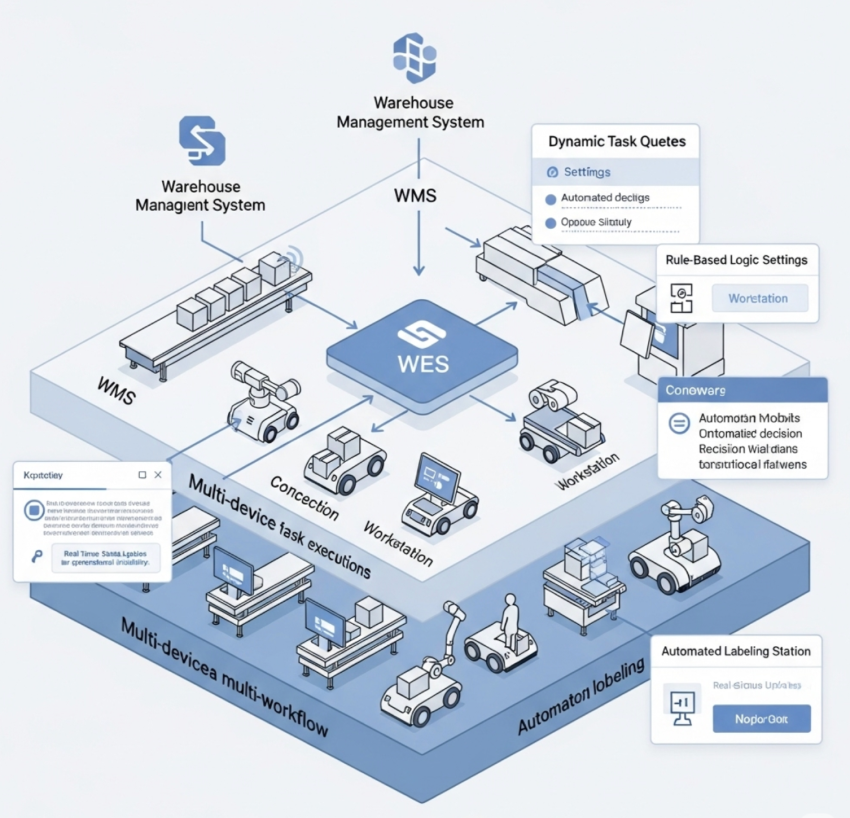

Smart Scheduling. Real-Time Control. Scalable Automation.

Real-Time Visibility. Smarter Operations. Lower Costs.

Real-Time Control. Smoother Flow. Smarter Coordination.

A powerful industrial-grade dispatching system supporting large-scale, multi-robot operations across mixed environments.

Simulate. Optimize. Deploy with Confidence.

Seamless Integration. Faster Rollout. Smarter Execution.