To address labor shortages and manage 400,000+ SKUs, W Customer deployed 280+ Tote AMRs in a 13,000 m² warehouse with 9.2m racks. The system enabled zoned storage, dynamic wave picking, and cross zone robot coordination.

Results included a 260% increase in picking efficiency, 263% more storage capacity, and reduced labor dependency.

The project was completed in just 5 months with a local U.S. team and full fire safety compliance.

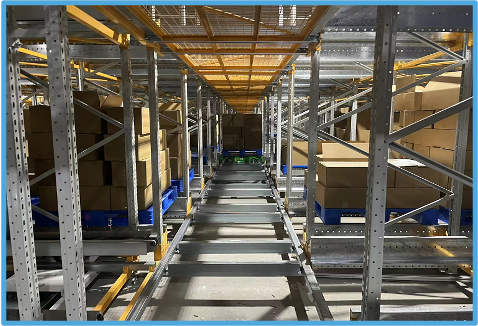

To address rapid growth, low picking efficiency, and high error rates, a pallet-to-person system was implemented for full pallet, case, and piece picking.

The solution included automated sorting, labeling, and pallet stacking. Results included an 80% boost in picking efficiency, 99.9% accuracy, 50% less labor, and reduced warehouse costs.

Phased deployment and intelligent task balancing support scalable, fast order fulfillment.

To maximize space and support more SKUs, a 4WS system with 20+ AMRs was deployed in a 3,000 m² warehouse. Reverse picking logic cut picking time by 60%, while weighing-based cycle counting eliminated manual inventory checks.

Elevated GTP design enabled base free pallet handling, reducing racking costs. The solution boosted storage capacity by 60%, cut labor by up to 35%, and improved automation and inventory efficiency.

A 30,000 m² warehouse was equipped with 4-way shuttles, 100+ GTP robots, 100+ sorting AMRs, and 4 robotic arms.

Robotic arms and AMRs worked together for automated labeling, dimensioning, and exception handling. By integrating traditional and flexible automation, the warehouse achieved a fully touchless operation.

Results included a 200% increase in storage capacity, ~60% labor reduction, and significantly improved inbound/outbound efficiency.

To support both B2B and B2C operations, a phased automation strategy was implemented at a Spain-based warehouse handling 120,000 pieces daily. Over 200 GTP robots were deployed, with shared AMR resources across zones to optimize space and meet seasonal peaks.

The solution delivered greater flexibility in an uncertain market, reduced labor intensity, and lowered operational costs.

A 13,700 m² warehouse with 9m clear height adopted a hybrid solution combining 4-way shuttles and GTP systems. The upper zone holds 14,550 pallet locations across 3 tiers, while the lower zone includes 3,481 GTP picking shelves.

Equipped with 10 shuttles, 3 hoisters, and 37 P800 AMRs, the system handles 36 pallets/hour inbound and 169 order lines/hour outbound. The solution enhanced storage density, reduced labor intensity, improved efficiency, and remains flexible for future growth.

To meet high storage demands and fluctuating order volumes, a flexible automation system was deployed using large GoPick robots for vertical tote handling and compact GoCarry robots for horizontal movement.

Intelligent multi-station scheduling and layered inventory management enabled rapid picking and scalable operations. The solution delivered over 1,000+ pcs/hour per station, reduced labor and space costs, and achieved ROI within 1–2 years.

To handle the complexity of diverse SKUs and mixed product types, a flexible automation solution was deployed for the MRO sector. Mobile robots enabled collaborative picking across automated and manual zones, with algorithmic task allocation tailored to SKU profiles.

The system improved storage efficiency by 26%, boosted operational efficiency by 35%, reduced forklift use, and enhanced accuracy in picking and inventory tracking—providing smarter insights for dynamic inventory strategies.

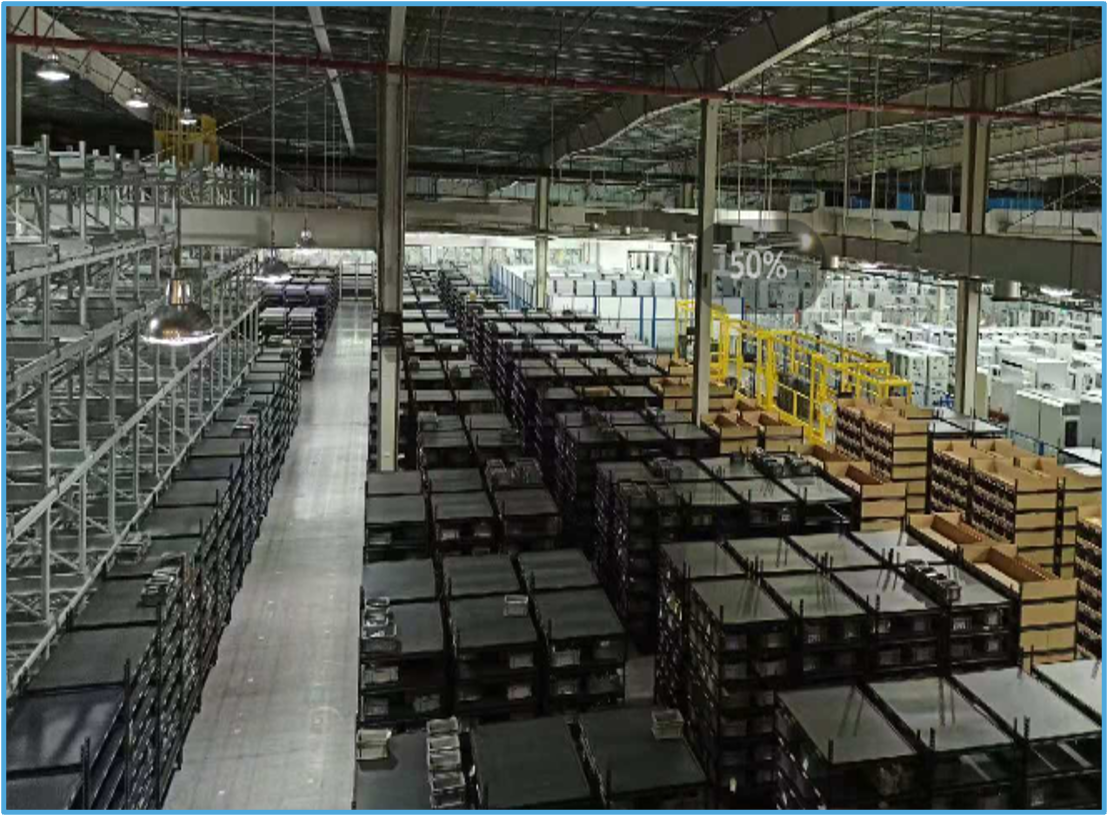

A major appliance manufacturer implemented a full process automation system covering production line transport, inter line handling, and finished goods warehousing.

The solution integrated mobile robots, lifts, robotic arms, and the MES through a unified dispatching platform. It enabled seamless multi-workflow coordination, flexible configuration, and real-time data integration.

The result was end-to-end automation, higher operational efficiency, fast adaptation to business changes, and a fault-tolerant system with no single point of failure.